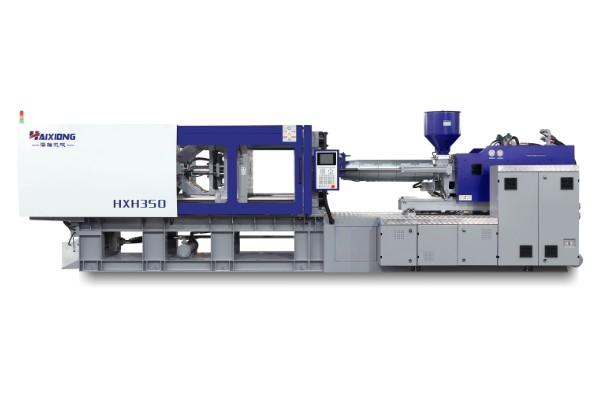

High speed injection molding machine

- The barrel is made of infrared heating and heating device

- with heating fast, efficient, energy saving, long life and other advantages

- Dynamic template position measurement using magnetostrictive displacement sensor

- Non-contact measurement, transmission of digital signals, accurate and reliable measurement data, high repeatability

Computer control system using CANbus EtherCAT and other bus communication, to achieve full digital control.

Temperature control using a dedicated control module, the accuracy of 1 degree.

With power monitoring function, can monitor the current production of energy consumption.

Dedicated single-cylinder injection structure, a significant reduction in high-speed injection of the amount of oil back, reducing the injection of the oil pressure, thereby increasing the machine when the injection speed.

At the elbow connecting rod and guide rod at the use of graphite steel sets, with thin oil lubrication, with better bearing capacity and wear resistance. So that the machine has a longer service life.

Switch mode action with proportional directional valve control, with the action to accelerate quickly, high-speed operation smooth, open mold position control precision features.

Hydraulic system uses dual servo drive control, with high efficiency and energy saving, low noise advantages, can realize a mold, storage material synchronization function.

Hai Xiong thin-walled high-speed machine series is in the years of experiment, based on the study specifically for short molding cycle, high-speed injection molding products with great concentration to create. In the movement characteristics, machine accuracy, life and other aspects of excellence.

Widely used in packaging plastic products, medical plastic products, 3C electronic products production.